I. Introduction

In hodiernae cursim developing industriae productio, packaging est a key gradus ex productio ad venditio. Et cessum plene automatic packaging machinery est vehementer amplio packaging efficientiam, reducitur laborem costs, et quoque melius consistency packaging qualis. Hoc articulum et de pertinet technologiae plene automatic packaging machinatione, comprehendo eius opus principium, clavis technologies, progressionem trends et applicationem areas.

II. Opus principium plene automatic packaging machinery

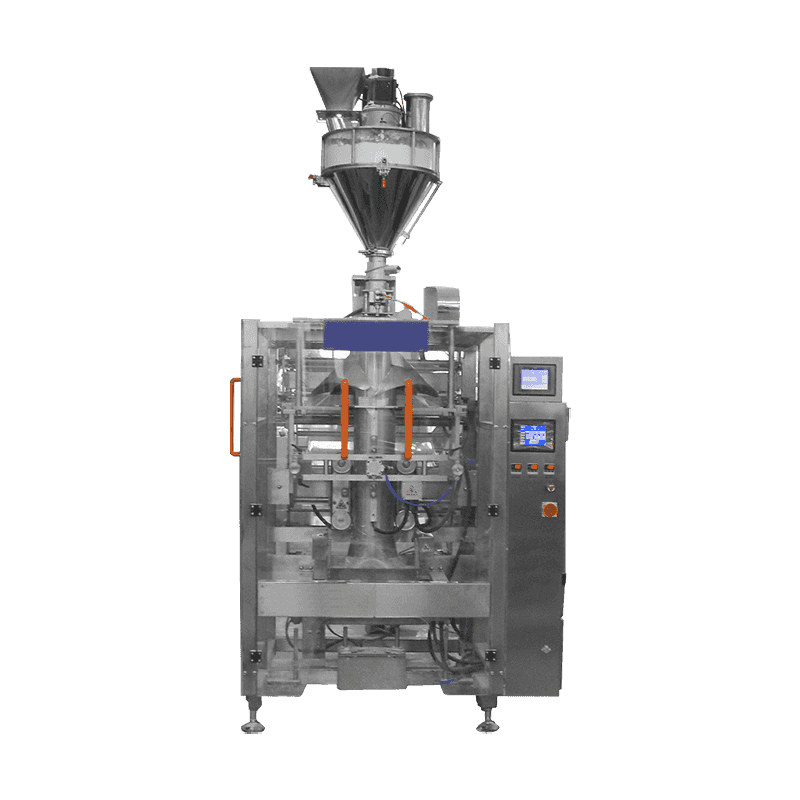

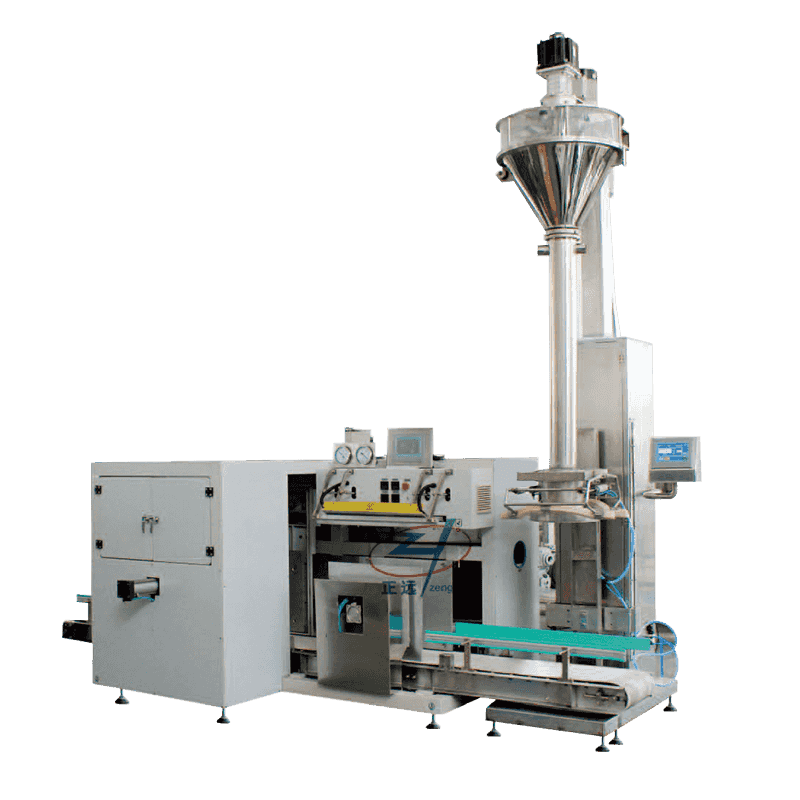

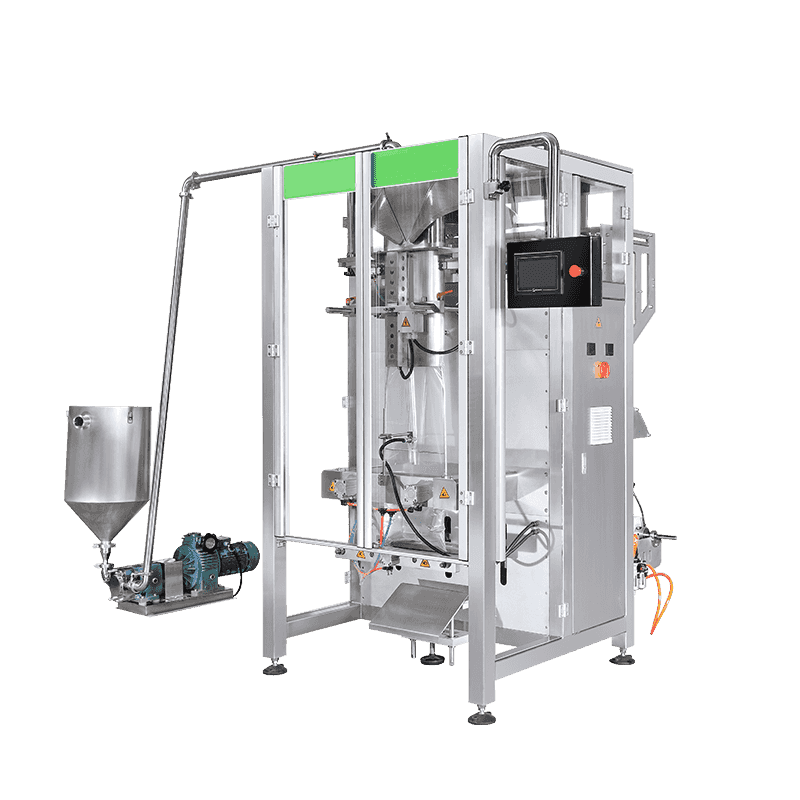

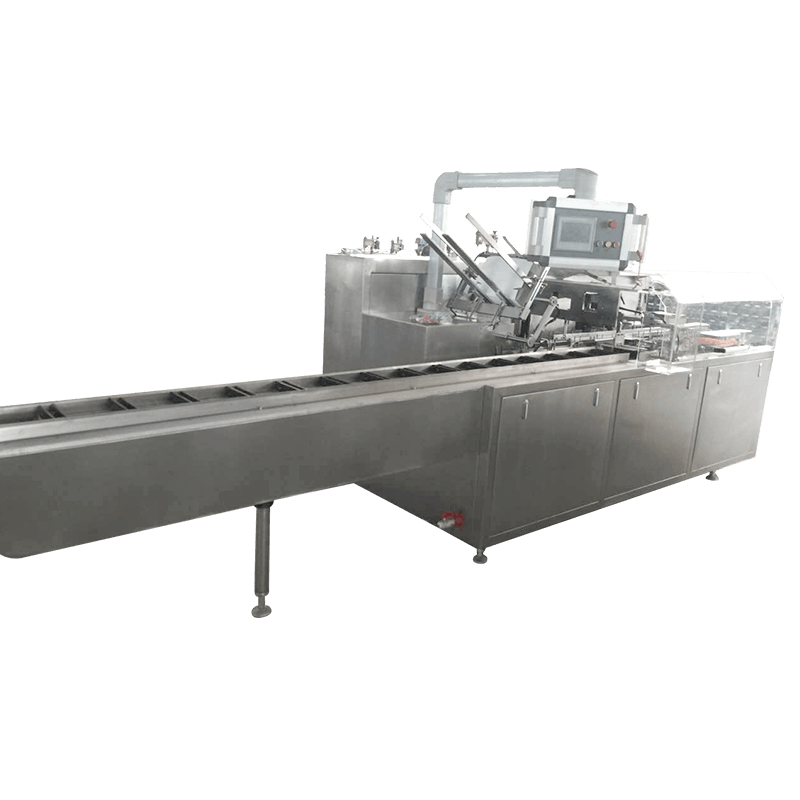

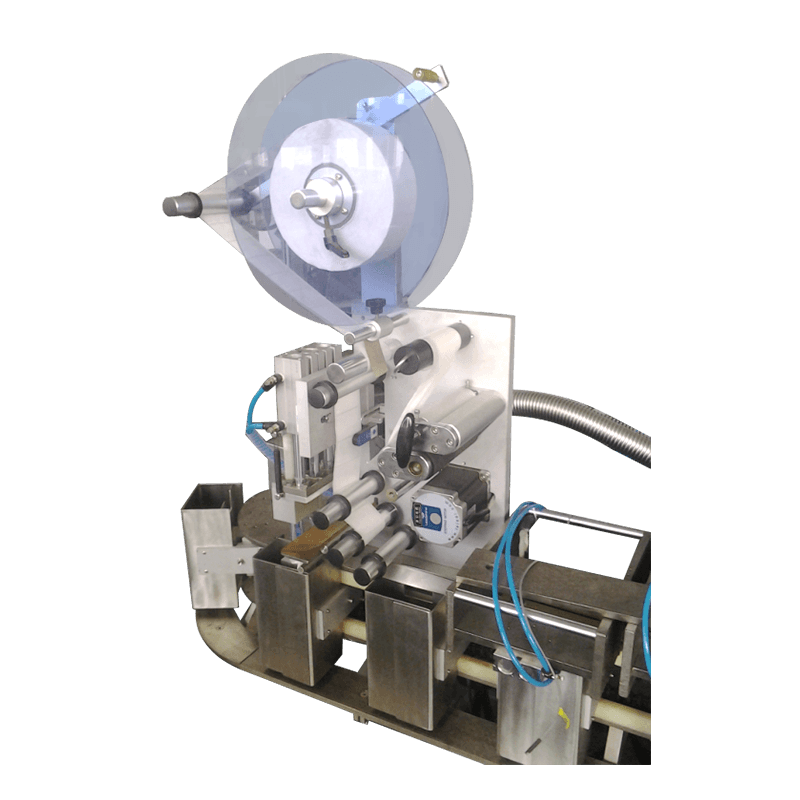

Plene automatic packaging machinery Solet composito ex multa systems, comprehendo materiam important ratio, packaging CUMATIUM ratio, saturitatem system, systema et complevit productum output ratio. In materia et ratio onerariis items vel rudis materiae ad packaged ad packaging situ; Packaging CUMATIUM ratio facit packaging materiae in idoneam figuras ut sacculos et boxes secundum packaging requisita; implet ratio accuratius implet items in packaging; Signatio sigilla signa packaging ut integritas packaging; Denique, et complevit productum output system outputs et packaged products ad subsequent processus et repono area. Totum processum coordinatur a automatic imperium ratio ad consequi continua et efficiens packaging operationes.

III. Technologies

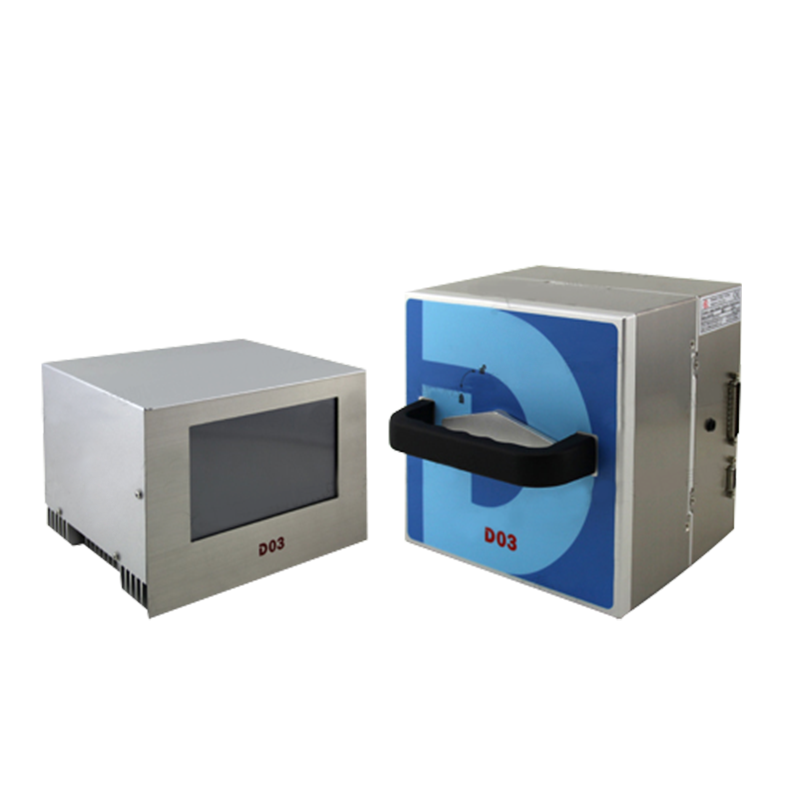

(I) Automatic Imperium Ratio

Automation Control ratio est core plene automatic packaging machinery. It uses provectus sensorem technology, programmable logica moderatoris (plc) et humana-machina interface (HMI), quod potest monitor et control quisque link of packaging processus in realis est. Sensors potest deprehendere locum, quantitas, status packaging materiae et alia notitia de materia, et pascat hoc notitia ad plc. In PLC pressius controls se component secundum est preset progressio ut accurate et stabilitatem in packaging processus. In HMI providet operators cum intuitive operationem interface ad parameter occasum, culpa diagnosis et vigilantia.

(II) Packaging Material Processing Technology

Et qualis et processus modum packaging materiae sunt crucial ad packaging effectus. Plene automatic packaging machinery indiget ut efficiens packaging materia dispensando capabilities, comprehendo materia, sectionem, formatam et redivivus. Exempli gratia, in film packaging, quod apparatus necessitates ad verius control tensio de film ne film a rugis aut solveret in packaging processus. In eodem tempore, ut in occursum environmental tutela requisitis, quidam packaging machina est etiam instructa packaging materia redivivus cogitationes ad redivivus et processum abdicavit packaging materiae ad redible resource et environmental pollutio ad redigendum resource et environmental pollutio.

(III) Filling Technology

Filling technology est unus ex key nexus de plene automatic packaging machinery. Diversis items eget diversis impletiones modos, ut liquidum, pulveris, granulares, obstructionum, etc. ad liquorem saturitatem, a summus praecisione metering sentinam vel piston sentinam non requiritur ad ut implens moles liquido est accurate; Nam pulveris et granula implens, vibrationis aut stupra implens fabrica plerumque solebat consequi accurate impletionem a moderante vibrationis frequency vel cochlea celeritas. Praeterea, quidam packaging machinis sunt etiam instructa cum automatic appendens ratio ad Monitor ad filling pondus in realis tempore per impletionem processus ad amplius amplio ad impletionem accuratissime.

IV. Development trends

(I) intelligentia

Cum enim progressionem artificialis intelligentia et Internet de rebus technologiae, plene automatic packaging machinery est movere ad intelligence. Per installing magis sensoriis et intelligentes cogitationes in packaging machinatione, realis-vicis vigilantia et data analysis de packaging processus potest fieri. Exempli gratia, apparatus vision technology est ad deprehendere specie packaging, automatice identify defectibus in packaging, utrum titulus situm accurate, etc.; Per Internet de rebus technology, in packaging machina connexa ad societatem scriptor productio administratione ratio ut animadverto remotis vigilantia, culpa et productio scheduling, etc., ut amplio gradu scheduling, ut amplio elit.

(II) flexibilitate

In modern productionem, quod diversificatio productum genera et packaging specifications posuit deinceps superioris requisitis packaging machinatione. Plene automatic packaging machinery indiget habere flexibile productionem capabilities et potest cito aptet ad packaging necessitatibus diversis products. De una manu, mechanica structuram consilio magis flexibile et repositoque aliquas partes aut adjusting parametri, switch packaging diversis specifications potest intelligi; on the other hand, the control system can quickly respond to changes in packaging specifications, automatically adjust the working parameters of each component, reduce mold change time and downtime, and improve production efficiency and equipment utilization.

(III) Green Environmental Tutela

Contra background of augendae global environmental conscientia, in viridi environmental tutela plene automatic packaging machinery quoque facti sunt progressionem trend. De una manu, packaging machinery manufacturers stipendium magis operam ad industria salute et consummatio reductionem in consilio et vestibulum processus, capere agentibus motores, industria, salute coegi systems et optimized mechanica structuris coegi systems et optimized mechanica structuris coegi systems et optimized apparatu In alia manu, develop et applicare magis environmentally amica packaging materiae, ut degradable materiae, charta materiae, etc, ad redigendum pollutio ad environment. In eodem tempore, in redivivus technology de packaging machinery est etiam semper developing, meliorem redivivus rate of packaging materiae et mechanica partes, et realizing ad redivivus de opibus.

V. Application agro

Plene automatic packaging machina late in multis industries ut cibum, medicina, eget industria et cotidiana necessaria. In cibo industria, quod est ad sarcina variis cibis, ut potiones, CUPPES, tortulas, cibum products, etc., ut ad curare MUNDITIA et salus cibum in translationem et repono; In pharmaceutical industria, quod est ad sarcina pharmaceutical capsules, tabellas unguenta etc., ut packaging qualis medicinae occurrit stricte pharmaceutical productionem cubits; In eget industria, quod est ad sarcina variis eget rudis materiae et products, ut liquido chemicals, pulveris chemicals, etc., ne eget leakagia et pollutio; In cotidie necessitatibus industria, ut ad sarcina stibio, baptismata commeatus, stationery et alia products ad amplio packaging AESTHETICA et foro aemulationem products.

VI. Conclusio

Ut magna pars modern industriae productio, in technology de plene automatic packaging machinatione continues ut develop et innovate. Et emendationem de key technologiae ut automatic control systems, packaging materia dispensando technology et implens technology providet a technology ad efficientem operationem packaging machinatione. In progressionem trend de intelligentia, flexibilitate et viridi environmental praesidio enables plene automatic packaging machinery ad meliorem aptet ad necessitates modern productionem. In late applicationem in multiple industries etiam promotus progressionem related industries. In futuro, cum adhuc profectus scientia et technology, plene automatic packaging machinery erit ludere a magis munus in meliorem productionem efficientiam, reducendo productio costs, ensuring uber qualitas et environmental praesidium.

Contact Us