In mundo, ubi celeritas, hygiene et consistency dominate industriae petit, packaging machinis et emerged sicut backbone efficient productum tractantem. Sive suus 'pharmaceuticals, cibum, stibio, aut electronics, packaging machinis ut products sunt facis confidenter, attrahitis, et in obsequio cum qualis signa. Hoc articulum explorat diverse genera, opus principiis, industriae applications et evolving technologiae post packaging machinis.

I. Quid est packaging apparatus?

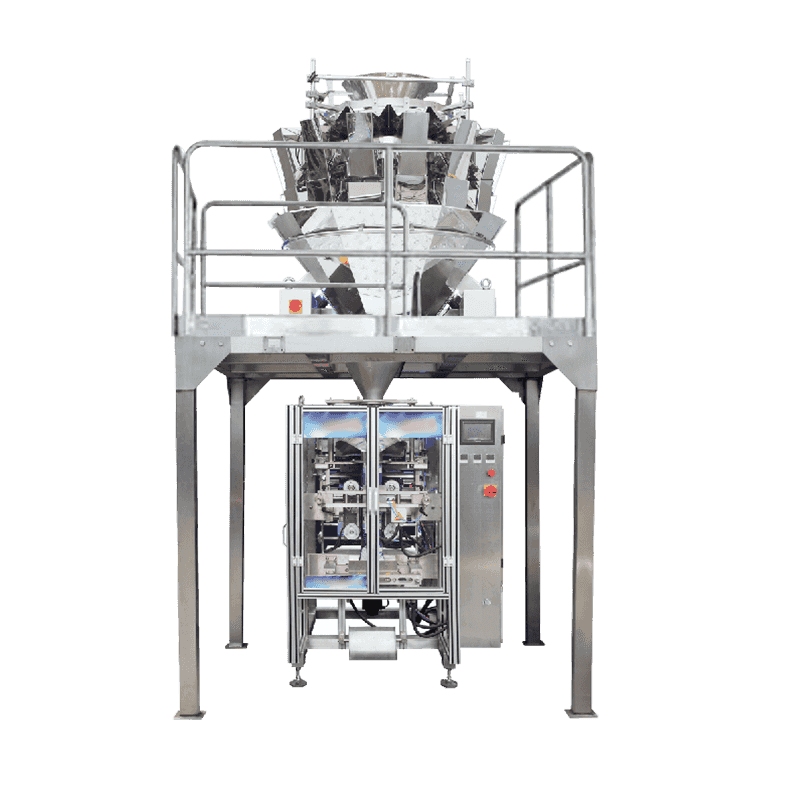

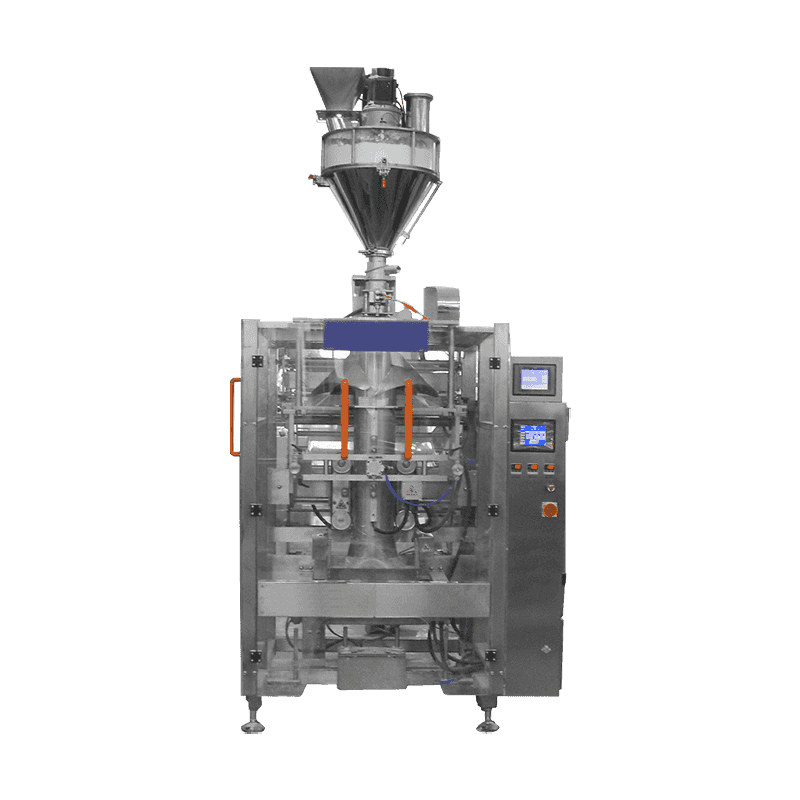

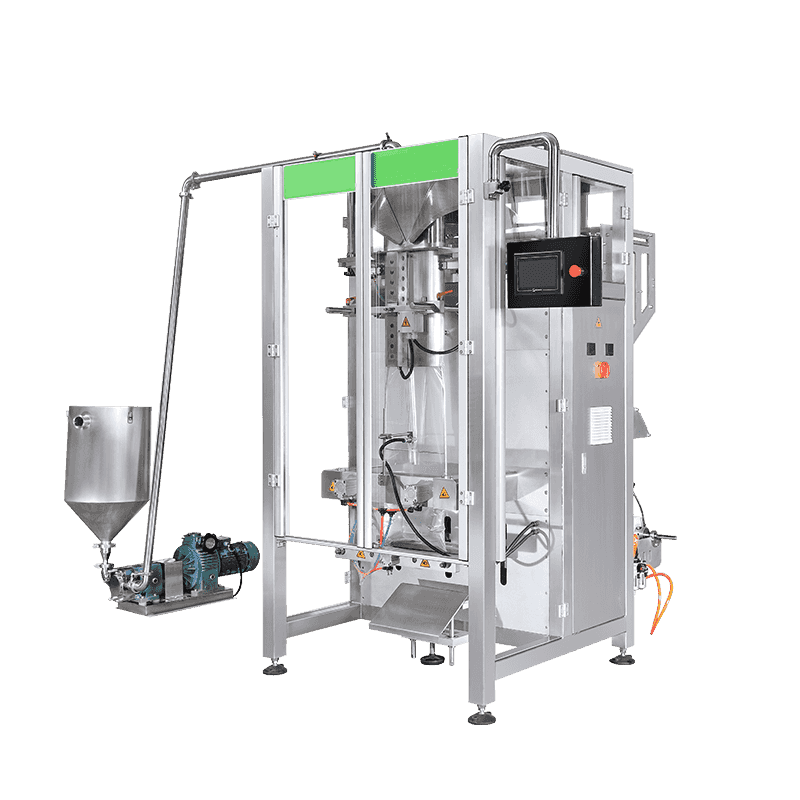

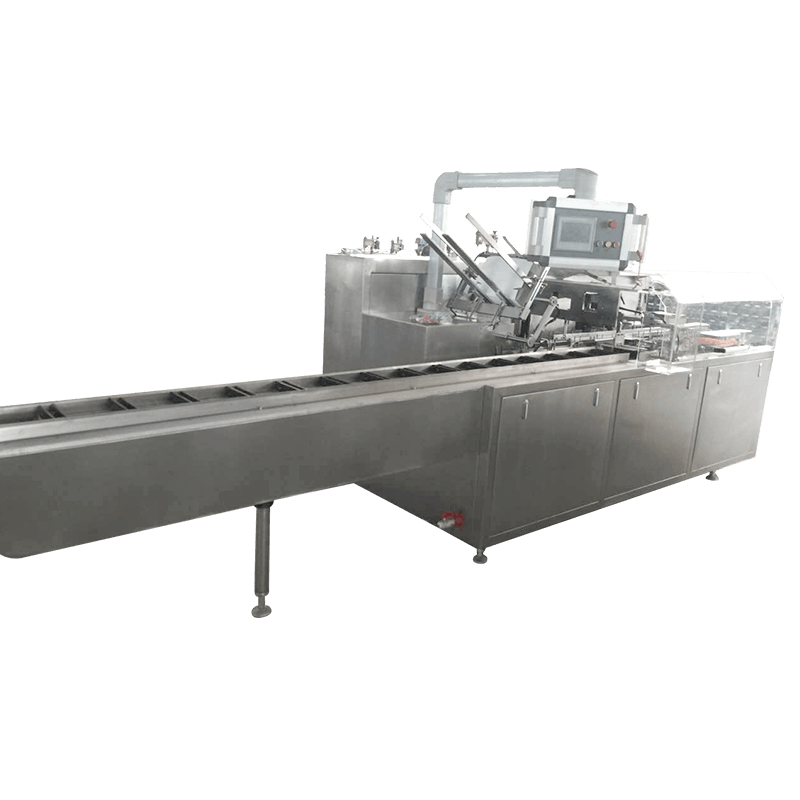

A packaging apparatus Est a fabrica vel ratio cogitationes disposiut ad automate in packaging processus bona. Potest tractare tasks vndique a implens, signantes, involuti et labeling to coding, palletizing Et quidem inspectionem . Haec machinis sunt tailored ad variis packaging formats ut utres, sachets, manticis, cann, blister sarcinas, cartons et Trays .

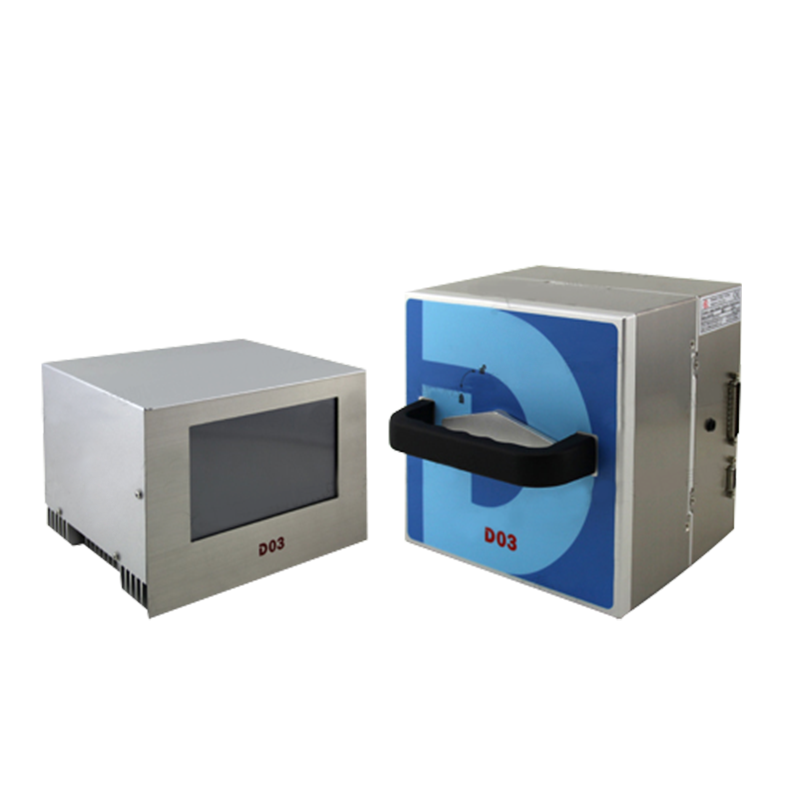

Modern packaging machinis sunt nectunt mechanica, pneumaticae, et servo-continet systems Et saepe integrated cum PLC controls , HMI Panel et dolor sensoriis nam realis-vicis vigilantia et operational imperium.

II. Classification Packaging Machines

Packaging machinis sunt geno munus, uber genus, aut packaging modum. Infra sunt primaria genera:

A. implens machinis

Ad dispensationem exigere quantitas productum in vasis.

-

Liquid implens machinis: Nam sucos, olea, oeconomiae.

-

Pulveris implens machinis: Nam conspersa aromata, lac pulveris.

-

Granule implens machinis: Nam rice, capulus, saccharo.

-

Volumetric et gravimetric fillers: Offer summus praecisione impletionem.

B. signa machinis

Create Airtight Closure protegere contentus et extend fasciae vitae.

-

SEALERS æstus: Usus temperatus ad sigillum plastic films.

-

Induction Sealers: Sigillum continentis operculis cum electro inductione.

-

Vacuum Synorers: Remove aeris et sigillum conservare perishables.

C. Wrapping velit

Wrap items in film aut ffoyle in praesidio et præsentationis.

D. Blister et habena packaging machinis

Commune in pharmaceuticals ad unitas-dose packaging.

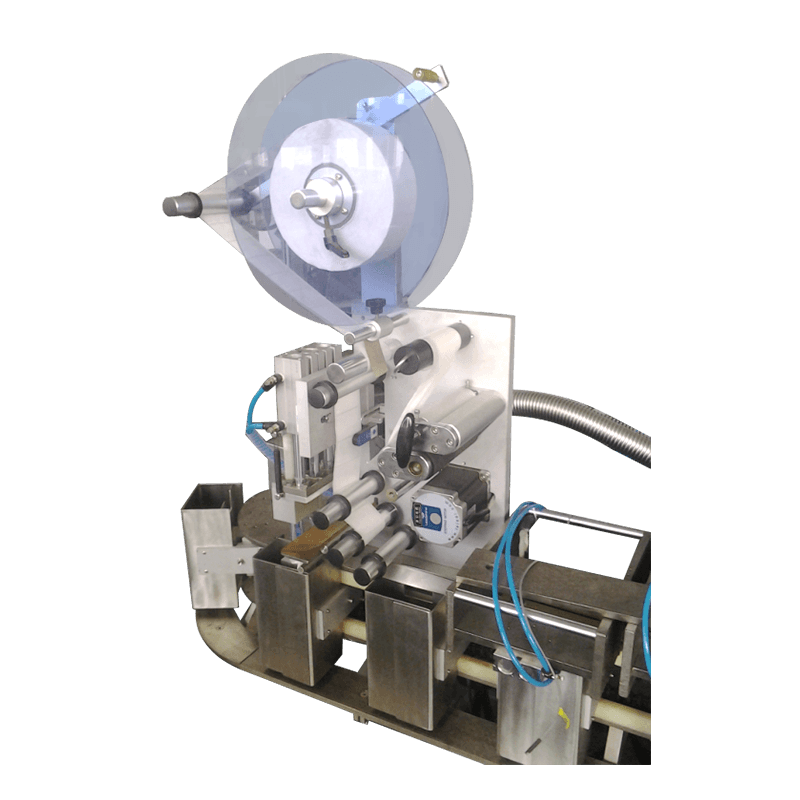

C. Labeling & Coding Morte

Applicare et print notitia ut Barcodes, expirata dies, et batch numero.

F. Cartooning et casus sarcina machinis

Automate in packaging products in cartons vel casibus.

G. Palletizing Morte

Usus est ad ultima scaena ad ACERVUS et involvent cartons onto grabatum naviculas.

-

Robotic paletizers

-

Conventional paletizers

III. Opus principiis packaging machinis

Quisque machina genus sequitur specifica sequentia secundum suam applicationem, sed maxime sequi hanc generalis structuram:

-

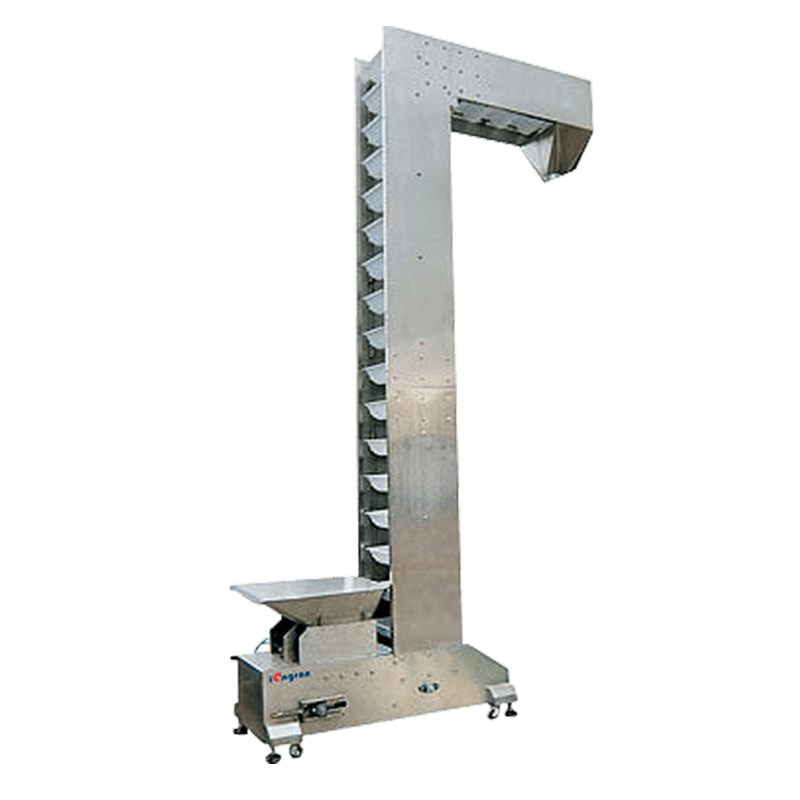

Product pascens: Manual aut automatic pascit per conveyors et Hoppers.

-

Mensurement vel deprehendatur: Using onus cellulis photoelectric sensoriis, aut visionem systems ut ius quantitas vel orientation.

-

Packaging materia tractantem: Film aut lobortis est evolvitur et informibus.

-

Filling / placing: Product is introduced in sarcina.

-

Signatio / Wrapping: Mechanica, scelerisque, aut ultrasonic signatio fit.

-

Labeling et coding: Ad libitum processus in vestigium et notans.

-

Defuncta / Sorting: Final Product est solutum ad conveytores et collectis in bins.

Multi modern machinis sunt integrated cum PLC (programmable logica moderatoris) , Motors servo , Automatic Culpa deprehensio et Longinquus diagnostic capabilities , Maxime in industria 4.0 occasus.

IV. Applications contra industries

Cibo potum

-

Sachechus packaging pro Sauces, condimenta

-

Vacuum signantes in cibum et caseum

-

Et bottling et capping pro juices aquae

Pharmaceuticals

-

Blister sarcinas ad tabulas

-

Spolia packaging ad Capsulae

-

Serialization et track et-vestigium coding

Cosmetics et personalis cura

-

Tubus implens enim crepito et lotions

-

Labeling de utres et dolia

-

Cartooning pro cohibenti sets

Chemical et Industrial Products

-

Pulveris fillers ad detergents

-

Tympanum implens ad pingit et lubricants

-

Signatio de Missa de Missa Rapidshare

E-commerce et logistics

-

Poly peram machinis et vestimenta sua

-

Automated buxum erectorum et sealers

-

Barcode Labeling et RFID Integration

V. Utilitates Packaging Machines

-

Maximum throughput: Potest sarcina millia unitates per hora.

-

Constantia & accurate: Ensures uniformis productum præsentationem et precise impletionem.

-

Hygiene & Safety: Minimizes humanae contactus, praesertim in sterile environments.

-

Sumptus sumptus reductionem: Automates repetita et tempus-perussi tasks.

-

Aliquam: Machinarum potest esse accommodata variis magnitudinum, formats et products.

-

Traceability: Integration cum coding systems sustinet copia torquem diaphanum.

VI. Modern trends et innovations

Dolor packaging machinis

Usurpo Ai et IOT Ut Monitor perficientur, deprehendere errores, et optimize productivity in realem tempus.

Sustainable Packaging

Machinarum disposito tractamus biodegradable films , charta-fundatur scutras et Minimal plastic .

Modularis systems

Patitur velox mutare et expansion sine redesigning tota linea-specimen pro negotiis cum varia Skus.

Vision et inspectionem systems

Integrated cameras et sensoriis inspicere products ad defectus, misprints, aut falsa pondera.

VII. Factors considerare cum eligens packaging apparatus

-

Product characteres: Viscositas, granularity, reactivity.

-

Desideravit output: Celeritas, numerum vices, batch magnitudinum.

-

Packaging Material: Film, ffoyle, pet, charta, carton.

-

Vestigia: Spatium disponibilitate et linea integration.

-

Automation Level: Manual, semi-automatic, aut plene automatic.

-

Regulatory obsequio: Maxime in cibo et pharma sectores (FDA, CE, GMP).

VIII. Sustentacionem et operational guidelines

Ut bene perficientur:

-

Praestare lubricatae et Purgato .

-

Reponere GERBOR (Sigilla, laminis, balteos) Proactively.

-

Monitor Software / Firmware Updates Si digital systems in usu.

-

Schedule calibration Nam sensoriis et implens systems.

-

Ponere a Recordum Downtime et Errores ad optimize efficientiam.

Contact Us