In hodiernae ieiunium, deambulavit industriae landscape, in packaging productio linea ludit a discrimine partes in cursus products sunt, efficaciter, et attrahite traditum est perussi. A cibo et potum ad pharmaceuticals, stibio et electronics, bene-optimized packaging productio linea est vitalis pro maintaining qualitas, reducendo costs, et morabantur competitive in global foro.

Quid est packaging productio linea?

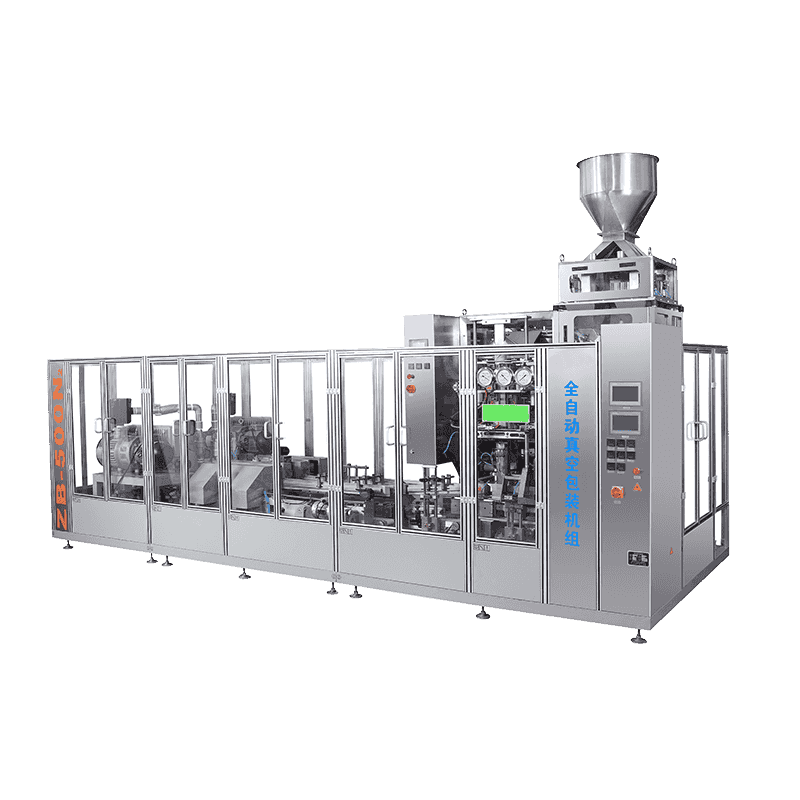

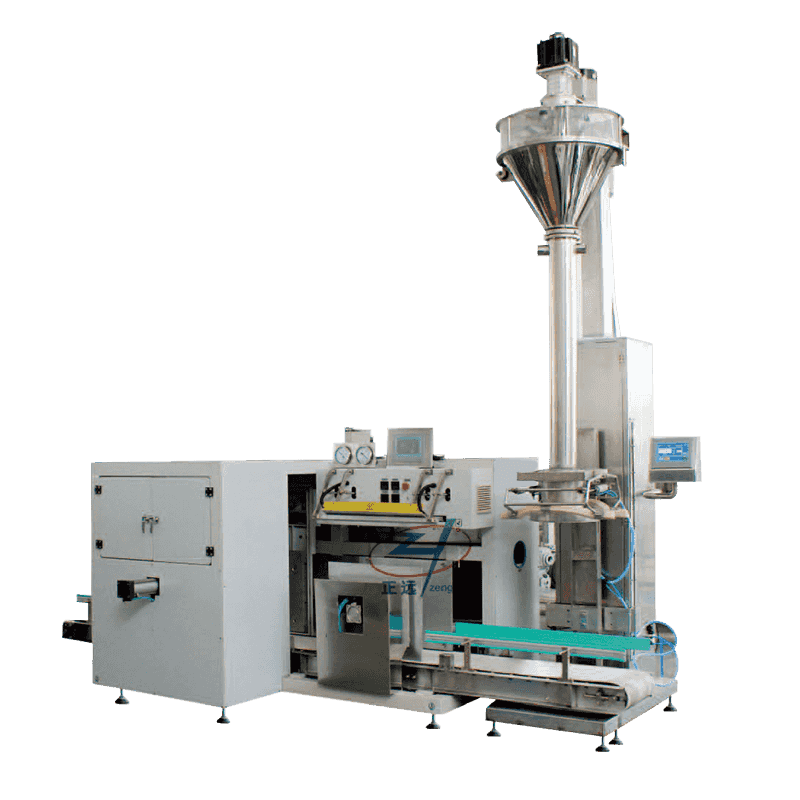

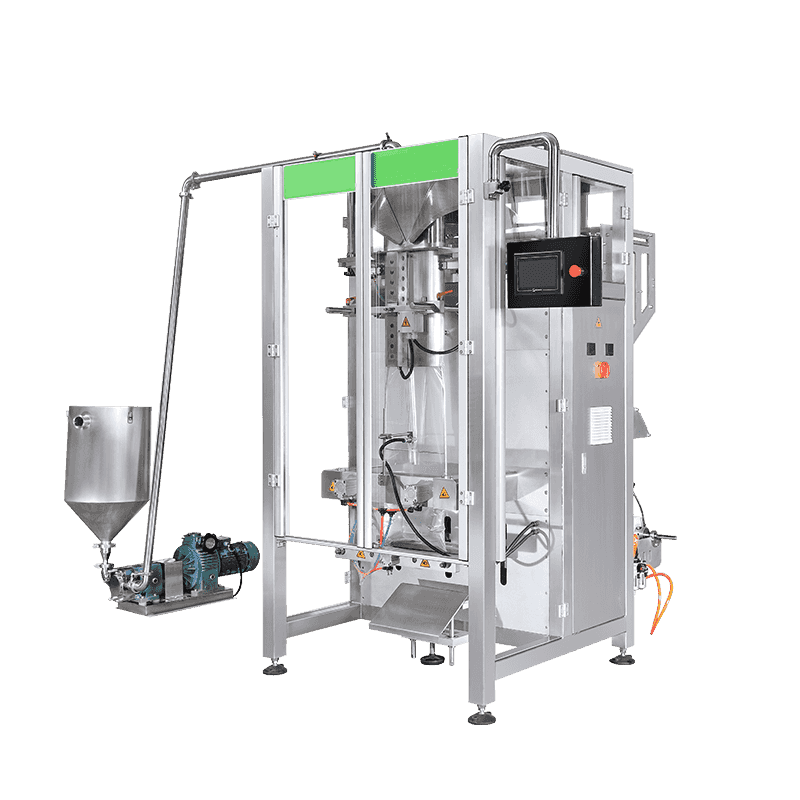

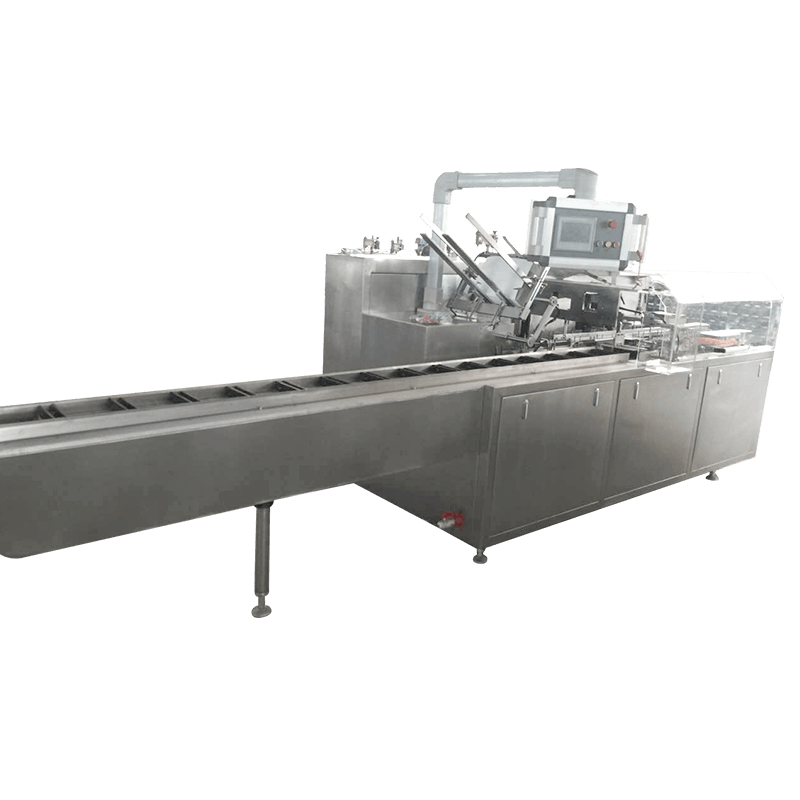

A Packaging productio linea Est integrated ratio composito ex multa machinis et technologiae disposito praestare specifica packaging officia in sequence. Haec tasks potest includere impletionem, seecting, labeling, coding, involuti, palletizing, et magis. Fretus in industria, in linea potest plene automated, semi-automated, aut manual, offering flexibilitate fundatur productionem volumine et operational necessitatibus.

Key components de packaging linea

Filling velit - Hi sunt ad satiata continentia, utres, aut manticis cum products sicut liquores, pulveri, aut solidorum. Precisione et Hygiene sunt crucial, praesertim in cibo et pharmaceutical sectores.

Signatio et capping velit - postquam implens, in packaging debet esse securely signatus vel capped ut novitatem et ne contaminationem.

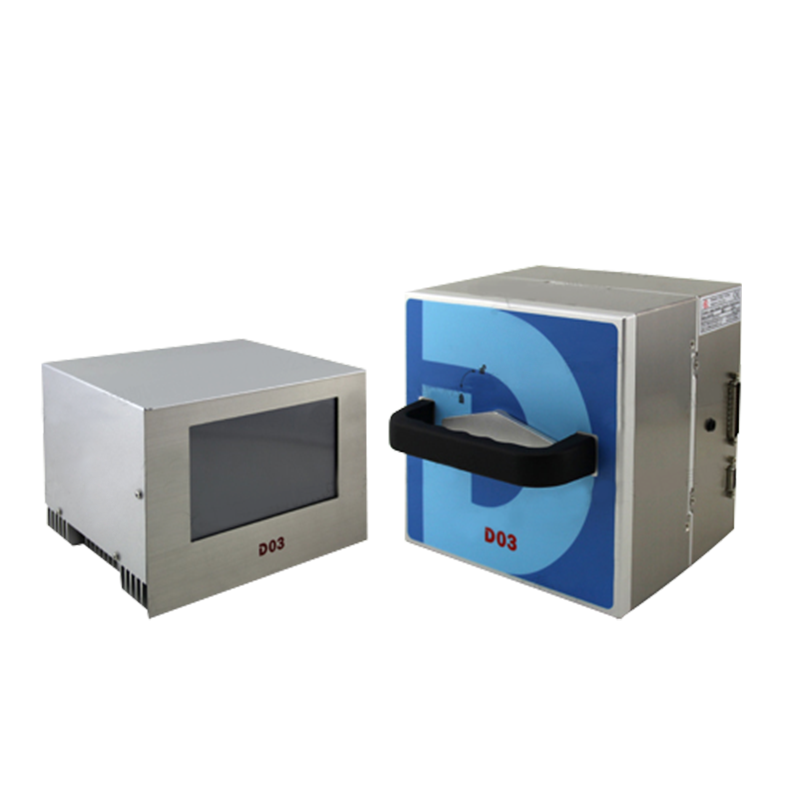

Labeling et excudendi Systems - Automated Labelers Applicare Product Labels, dum typographos Add Batch Codes, Barcodes, aut Expiration Dates pro Traceability et obsequio.

TRADUCTOR - Haec systems onerariam products ab uno statione ad alium, enhancing celeritate et constantia per processus.

Inspectionem Systems - Advanced vision et pondus-reprehendo apparatu auxilium ponere qualitas potestate per detectionem defectibus vel repugnantia.

Cartooning et Pullcetizing - In fine linea, products sunt grouped, cohibenti, et reclinant ad amet aut repono.

Beneficia an automated packaging linea

Auxit productivity: automated systemata potest operari 24/7 cum minimal downtime, significantly augendae output.

Consistent qualis: Uniform packaging reducit humana errore et ensures uber integritas.

Pretium Efficens: Reducitur laborem costs, materia vastum et productio errores translate in substantial peculi.

Scalability: lineae potest upgraded aut mutatio accommodare novum products vel mutantur foro petit.

Data Integration: Modern Lines Support Digital Cras et Reporting pro Potius Production Management.

Customization et industria applications

Packaging lineae potest esse nativus in occursum unicum requisitis diversis industries. Nam cibo et potum lineae focus in MUNDITIA et celeritate, cum pharmaceutical packaging extollit praecisione et obsequio cum regulatory signa. Cosmetics packaging lineae ut requirere delicata tractantem et aesthetic finit, cum industriae packaging focuses in diuturnitatem et mole tractantem.

Future trends in packaging productio lineae

Dolor Automation: AI et IOT Technologies concedit realis-vicis vigilantia, predictive sustentacionem et adaptive imperium packaging processibus.

Sustainability: Eco-amica materiae, minima packaging consilia, et industria-agentibus machinis sunt becoming key considerations.

Flexibilitate: modularis systems patitur pro vivos mutare inter diversas productum genera aut packaging formats.

Humanum-Apparatus Collaboration: Cobots (collaborative Robots) sunt adoptati ut adiuvaret humana operarios, meliorem salutem et efficientiam.

Conclusio

A modern packaging productio linea est quam iustus a serie machinis-suus 'a critica pars a comitatu est operational victoria. Per leveraging latest in automation, technology et consilio, negotiis potest augendae productum præsentationem, reducere costs, et respondere celeriter ad forum necessitates. Ut innovation continues ad agitare industria deinceps, packaging lineae non tantum facti sunt magis intelligentes, sustineri, et adaptabile.

Contact Us